Conclusion

Conclusion

Conclusion

The advantages of adopting a Smart Regulator approach are manifold. First and foremost, businesses benefit from reduced compliance costs. By automating routine compliance checks and utilizing real-time data, organizations can allocate resources more effectively and reduce the burden of manual compliance tasks. This, in turn, fosters innovation, as businesses can dedicate more time and energy to product development and market expansion rather than being ensnared in bureaucratic processes.

At the core of any pressure reducing regulator is a pressure-sensing mechanism. When the upstream pressure (inlet) exceeds the set point, the PRR automatically adjusts an internal valve, limiting the downstream pressure (outlet) to a predetermined level. This regulation maintains a constant output pressure even when there are fluctuations in the inlet pressure or variations in flow rates. Most regulators incorporate a spring-loaded diaphragm that responds to changes in pressure, creating a reliable feedback loop that maintains stability.

What are Gas Pressure Vessels?

The HVAC industry also benefits from electric regulating valves, as they help in managing air and water flow in heating and cooling systems. By ensuring that the right amount of air or water circulates at the right temperature, these valves play a significant role in energy conservation and operational efficiency.

Gasification presents several advantages over traditional waste-to-energy technologies

Natural gas pressure reducers come in several types, each designed for specific applications

Advantages of Using Pressure Reducing Valves

Economic Impact

- Petrochemical Industry In the petrochemical sector, gas pressure reducers are used to control the flow of natural gas and other gases during processing and transportation.

LPG is highly versatile and can be utilized in various sectors. In residential settings, it is widely used for cooking, heating water, and heating homes. In commercial spaces, restaurants and hotels often rely on LPG for cooking and heating. The industrial sector also benefits from LPG, as it can be used as a fuel for machinery, a feedstock for petrochemicals, and a heating source in manufacturing processes. Its adaptability makes it a preferred choice for many businesses seeking efficient and reliable energy sources.

In conclusion, gas filters are indispensable in the quest for cleaner air and better health. By effectively removing harmful gases from various environments, they help safeguard human health and protect the planet. As technology continues to evolve, the future of gas filtration looks promising, determined to meet the challenges of air quality management and environmental protection head-on. Understanding and utilizing these vital tools is essential for industry professionals, homeowners, and policymakers alike in promoting a cleaner, safer world.

Moreover, as the demand for natural gas continues to grow, especially with the shift towards cleaner energy sources, pressure reduction stations may also face increased pressure to perform efficiently. Operators must routinely assess capacity needs and potentially upgrade equipment to accommodate growth in demand.

After the separation of liquids, the purified gas exits through the outlet, ready for downstream processing or distribution. Meanwhile, the separated liquids are often routed to a collection system for further treatment or disposal.

Mounted equipment typically includes a wide range of tools that can be utilized in various fields such as construction, agriculture, and manufacturing. These tools are often fixed onto a slider, which serves as a movable base, facilitating seamless transportation and operation. The slider mechanism allows the equipment to be easily repositioned, making it ideal for tasks that require portability and adaptable configurations.

Understanding Gas Heat Exchangers

2. Compression Units Compressors play a critical role in moving gas through the pipelines. These machines increase the pressure of the gas, enabling it to flow efficiently over long distances. Some distribution stations may also contain additional compressors to maintain pressure levels as the gas is distributed.

1. Preventing Explosions One of the most pressing dangers associated with natural gas is the risk of explosions caused by pressure build-up. Safety valves automatically activate to release gas when pressure exceeds a predetermined limit, thereby preventing dangerous situations.

PRS stations are vital for several reasons. First, they enhance safety by ensuring that gas is delivered at safe pressure levels for use in homes and businesses. High-pressure gas poses serious risks, including explosions and infrastructure damage, making proper regulation crucial for public safety.

2. Thickness and Dimensions The wall thickness of the vessel is directly related to the pressure it will contain. Engineers must calculate the necessary thickness using formulas derived from the material's yield strength and the operational pressures expected.

In many industrial and commercial applications, maintaining adequate pressure levels is imperative. Excess pressure can lead to equipment failure, leaks, and accidents, creating unsafe environments and potentially causing significant financial losses. Beyond safety, effective pressure control is essential for optimizing process efficiency. For instance, in water distribution systems, PRVs help maintain consistent water pressure, preventing wastage and ensuring that consumers receive reliable service.

On a personal level, Al-Muthabit encourages individuals to cultivate resilience and stability in their lives. In the face of adversity, having a strong sense of self and a clear understanding of one’s values can serve as a guiding light. This aspect of Al-Muthabit calls for introspection, where individuals assess their beliefs and experiences, affirming what truly matters to them. Such reflection fosters a sense of purpose and direction, enabling one to navigate life’s challenges with confidence and clarity.

Data security and privacy are paramount concerns when implementing intelligent systems. Notably, many intelligent organizers now prioritize robust encryption protocols and allow users to customize their data-sharing preferences. This reassures users that their personal information and professional data are well-protected. The transparency surrounding data usage is also crucial, as it builds trust between users and service providers.

The city gate station is a bustling hub of activity, serving as a vital link between the city and its surrounding areas. This transportation center is a gateway for travelers, commuters, and tourists alike, providing a convenient and efficient way to access the various destinations within the city.

In conclusion, relief valves (صمام التنفيس) are indispensable safety devices that play a crucial role in the protection of industrial systems. Their ability to prevent overpressure conditions safeguards both equipment and personnel. As industries continue to face the challenges of maintaining operational safety amidst increasing pressures, the importance of reliable and well-maintained relief valves cannot be overstated. Emphasizing education on their proper usage and maintenance can further enhance safety protocols, thereby supporting the overall health, safety, and sustainability of industrial operations.

Conclusion

In summary, shut-off valves are integral to various fluid control systems, providing essential functionality for safety, maintenance, and operational efficiency. Understanding the different types and their applications is crucial for selecting the right valve for specific needs. As technology continues to evolve, the design and capabilities of shut-off valves will likely improve, further enhancing their role in various industries.

1. Single-Stage Regulators These regulators reduce pressure in a single step from the input to the output. They are straightforward and typically used in low-pressure applications where precision is not critical.

Moreover, pressure reducing valves play a critical role in enhancing the performance of hydraulic systems. By controlling pressure, they ensure that the hydraulic fluid is delivered at the right pressure for optimal operation of actuators and other components. In processes such as manufacturing and material handling, this precise control is vital for achieving desired outcomes.

2. Pneumatic Regulators Often used in larger systems, these regulators utilize compressed air to control pressure levels. They are particularly beneficial in applications requiring precise pressure regulation.

At the most basic level, a gas filter operates by capturing unwanted gases and particulates from a gas stream. They are commonly used in industrial settings, laboratories, commercial buildings, and even in residential environments. The design and function of gas filters can vary significantly depending on their intended use, with several types available, each catering to different types of contaminants and filtration needs.

Even Heat Distribution: Black cast iron griddles and grill pans distribute heat evenly, ensuring that food is cooked consistently and thoroughly. This feature is essential for achieving optimal searing and browning of meats and vegetables.

This is particularly useful for dishes that require precise temperature control, such as sauces, stews, and roasts This is particularly useful for dishes that require precise temperature control, such as sauces, stews, and roasts

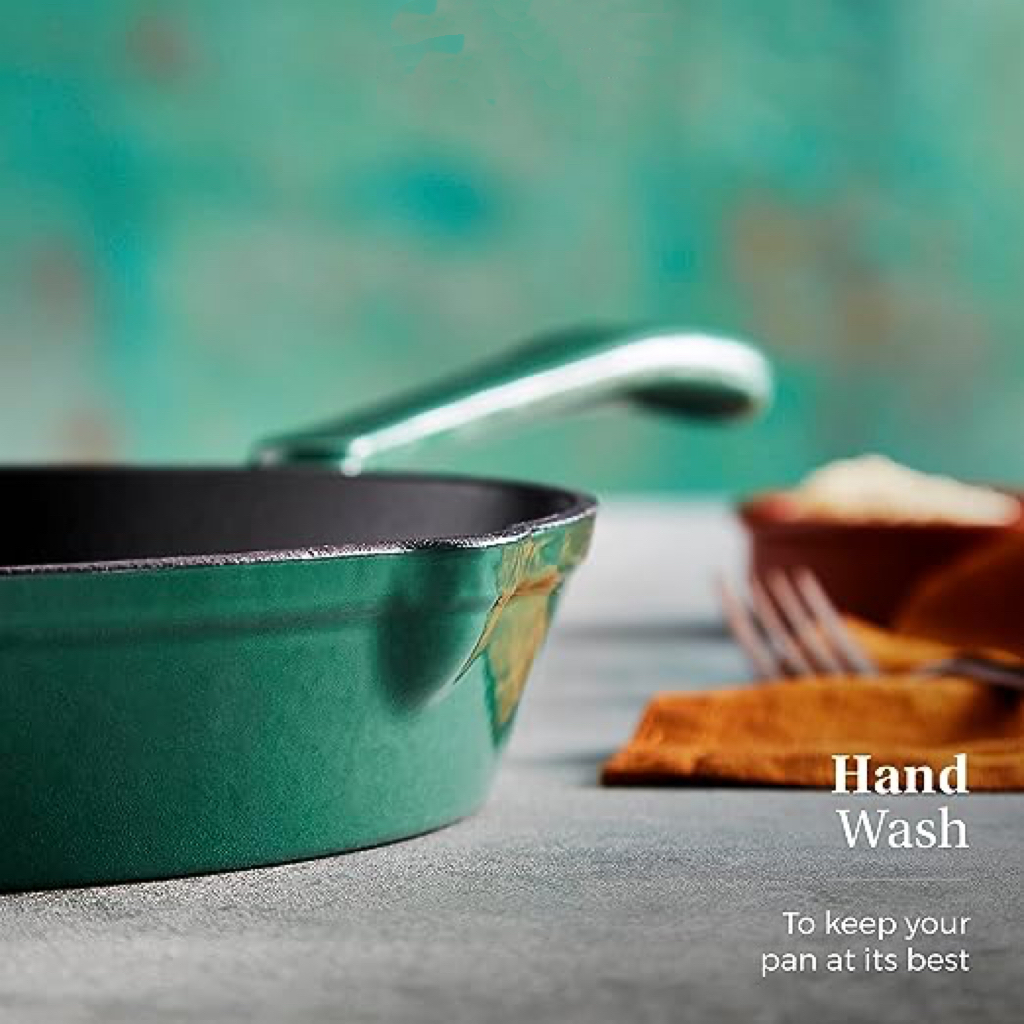

This is particularly useful for dishes that require precise temperature control, such as sauces, stews, and roasts This is particularly useful for dishes that require precise temperature control, such as sauces, stews, and roasts non stick enamel cookware. The even heat distribution also helps to prevent hot spots, which can cause food to burn or stick to the bottom of the pan.

non stick enamel cookware. The even heat distribution also helps to prevent hot spots, which can cause food to burn or stick to the bottom of the pan.

This feature is particularly beneficial for dishes that require a gentle simmer or a gradual braise This feature is particularly beneficial for dishes that require a gentle simmer or a gradual braise

This feature is particularly beneficial for dishes that require a gentle simmer or a gradual braise This feature is particularly beneficial for dishes that require a gentle simmer or a gradual braise polished cast iron frying pan.

polished cast iron frying pan.For those looking for a more personalized option, custom cast iron griddles are available, allowing users to tailor the size and functionality of the skillet to their specific needs. Whether it's a unique shape or specific size requirements, custom cast iron griddles can provide a personalized cooking experience for those with specific cooking needs.

Some people believe there is little difference between the two, while others disagree. Their similarities and differences are evident. The only significant distinction between skillets and pots is that skillets are deeper. They are typically at least 2 inches deeper (including the lid) than frying pans.

Sizzling plates are popular kitchenware items used for serving and cooking sizzling hot dishes. They are designed to retain heat and keep food sizzling hot as it is served to the table. Here, we will explore the materials used to make sizzling plates, where to buy them, and their various uses.

After cooking, your cast iron griddle must be properly cleaned. Contrary to popular belief, it is safe to clean griddle on the stove. Once the cast iron griddle has cooled slightly, sprinkle some coarse salt on the surface and wipe away any food residue with paper towels. The salt acts as a mild abrasive to remove bits stuck to the cast iron griddle without damaging the skillet's seasoning. After the cast iron griddle is clean, wipe it with a damp cloth and dry it thoroughly.

When using a cast iron griddle on an electric stove, it's important to make sure the skillet is properly seasoned. Seasoning your cast iron griddle creates a non-stick surface and prevents rust. To season the cast iron griddle, coat the cooking surface with a thin layer of vegetable oil and heat on the stove until it starts to smoke. Repeat this process a few times and your cast iron griddle is ready to use.

It can be used in cooking at high temperatures.

Each pot, with its possible chips and scratches, tells a story of meals past and memories made Each pot, with its possible chips and scratches, tells a story of meals past and memories made

Each pot, with its possible chips and scratches, tells a story of meals past and memories made Each pot, with its possible chips and scratches, tells a story of meals past and memories made blue enamelware pot. It symbolizes resilience and the beauty of imperfection, reminding us that life's most cherished moments are often those imbued with authenticity and history.

blue enamelware pot. It symbolizes resilience and the beauty of imperfection, reminding us that life's most cherished moments are often those imbued with authenticity and history. dutch oven 9qt. Whether you're searing meat on the stove before braising in the oven or baking a homemade loaf of bread, this oven provides a convenient one-pot solution. Its sturdy handle design allows for safe and secure handling, even when filled to the brim.

dutch oven 9qt. Whether you're searing meat on the stove before braising in the oven or baking a homemade loaf of bread, this oven provides a convenient one-pot solution. Its sturdy handle design allows for safe and secure handling, even when filled to the brim.A:The disadvantages of using copper core frying pans include their high cost and their tendency to discolor with prolonged use.